53 Organization Concepts And Financial Investment Chances In Zambia 20…

페이지 정보

작성자 Leland 메일보내기 이름으로 검색 | 작성일 24-01-19 14:03 | 조회 541회 | 댓글 0건관련링크

본문

Slicing generally suggests slicing a 3D version into hundreds or thousands of layers and is made with cutting software application. With volumetric printing whole structures can be formed at once without the need for layer-by-layer construction. It's worth keeping in mind, nevertheless, that since now, volumetric technology is largely in the research study stage.

Filaments And Artistic Wall Murals Materials Utilized In 3d Printing

Additionally described as SL, optical fabrication, please click the next site photo-solidification, or resin printing. New Bioprinter Makes It Easier to Make 3D Flesh and Bone by Eliza Strickland. Besides substitute body components, 3D printing is increasingly being used for medical education and learning and training. At Nicklaus Children's Healthcare facility in Miami, Florida, specialists practise surgical treatment on3D-printed reproductions of kids's hearts. Rarely the realm of enthusiasts, 3D printing is poised to overthrow manufacturing and reinvent aerospace. They can be available in steel, brass, bronze and copper so as to get the true feel and look of a metal object.

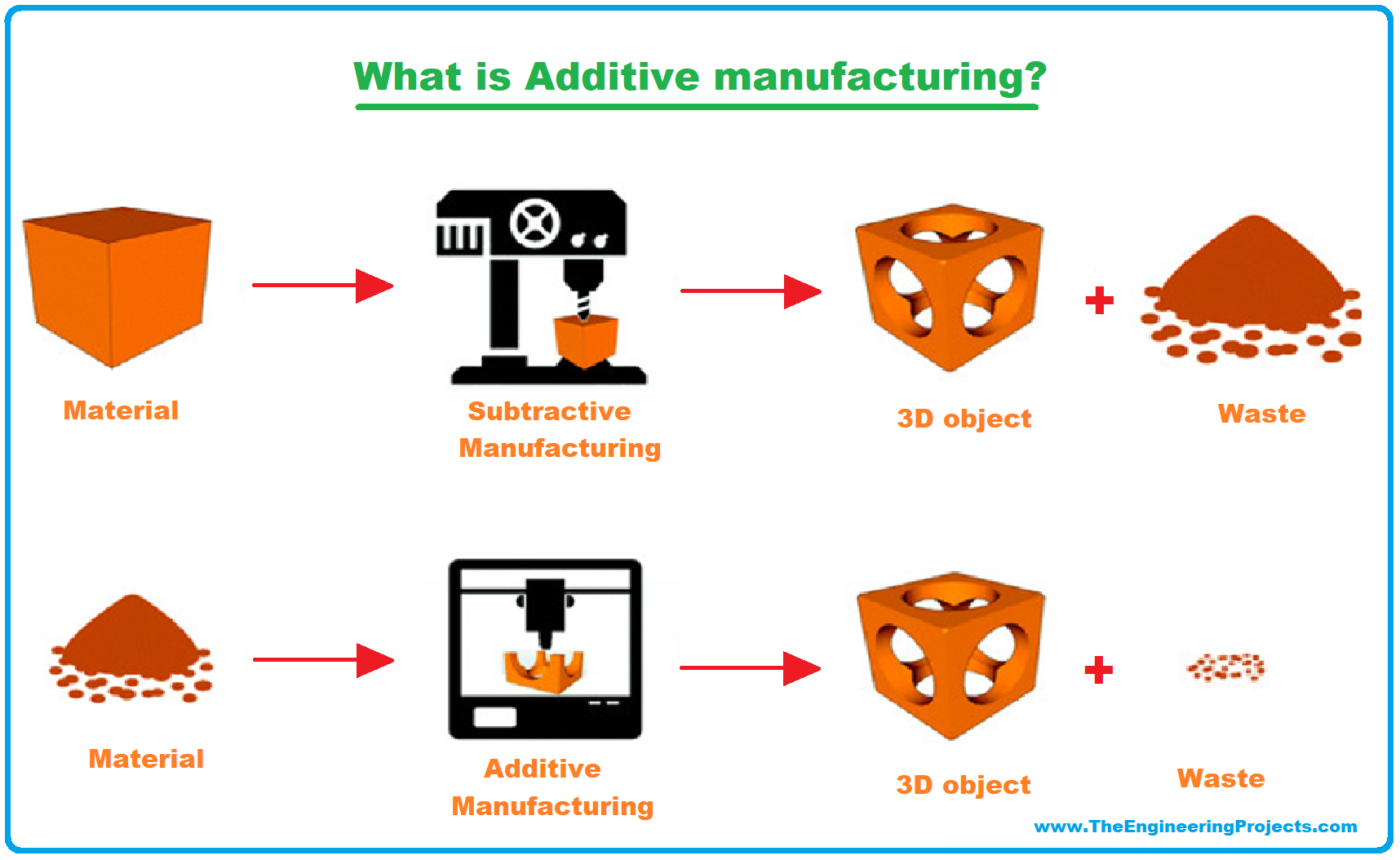

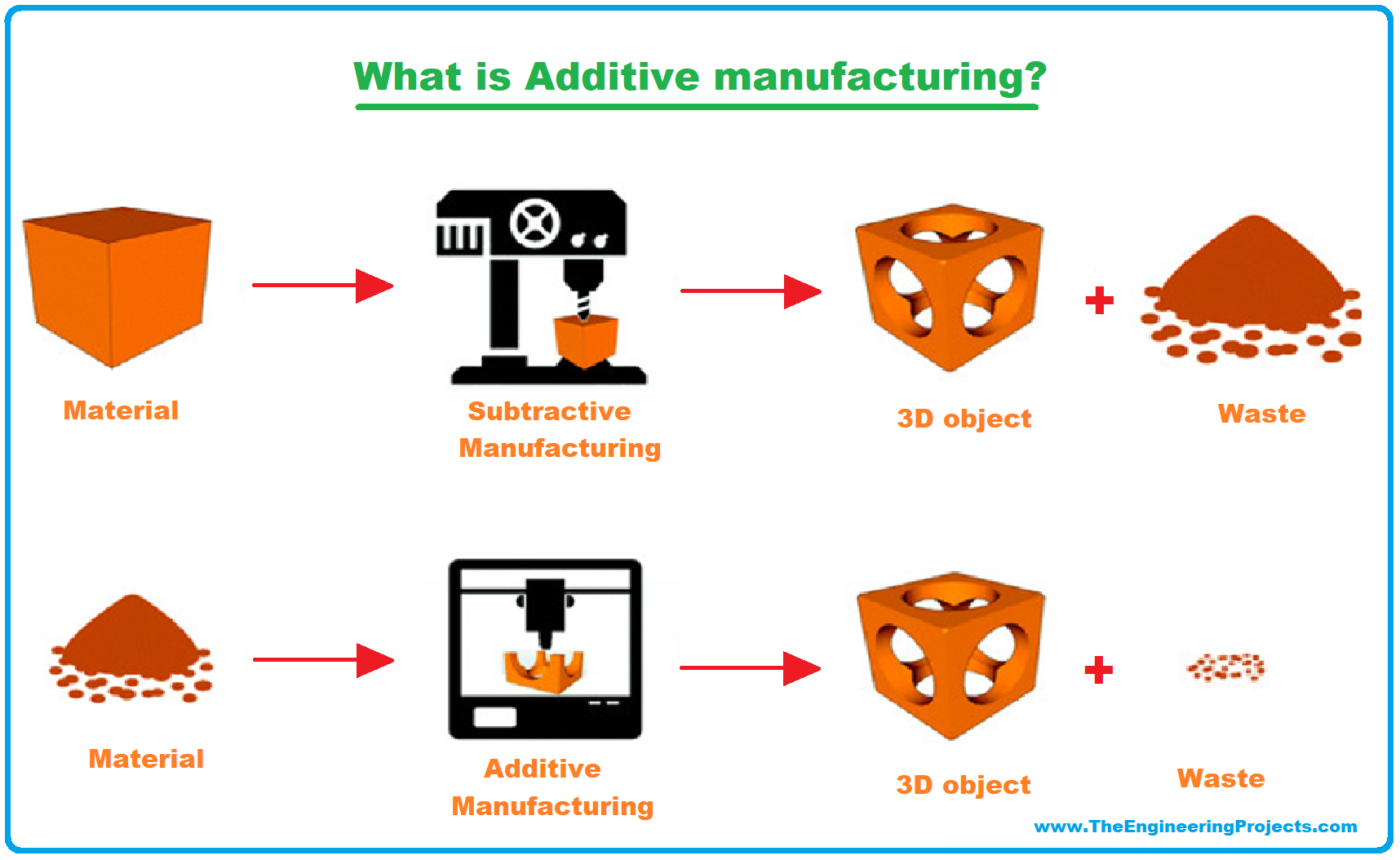

Additive manufacturing, starting with today's infancy period, requires manufacturing companies to be flexible, ever-improving users of all offered modern technologies to remain affordable. The real assimilation of the newer additive technologies into industrial production, however, is a lot more an issue of matching standard subtractive techniques rather than displacing them totally. Fluid additive production is a 3D printing method that deposits a fluid or high viscose product (e.g. liquid silicone rubber) onto a develop surface area to develop an object which after that is vulcanised making use of heat to solidify the things. The process was originally developed by Adrian Bowyer and was after that built upon by German RepRap.

Innovation

The product utilized in 3D printing is typically in the kind of a filament or a resin. Filaments, such as thermoplastics or metals, are fed right into the printer and melted at a certain temperature before being extruded click through the next article a nozzle. Resins, on the various other hand, are treated using ultraviolet light or various other methods. As soon as the design documents prepares, it is transferred to the 3D printer, which after that equates the electronic model right into a physical item. The printer accomplishes this by transferring material layer by layer, adhering to the guidelines encoded in the layout documents.

Just how much resistance you agree to approve is pretty much your phone call, however there are methods for you to decrease the tolerance you can get out of your 3D printer. These actions can be summarized as absolutely nothing greater than picking the appropriate product and doing routine maintenance on your maker. Appropriate calibration plays a big part-- we suggest finding out the best practices on calibrating your 3D printer's various components. Fine information in a model are a bit harder to define, as they are typically a mix of several printing specifications. Unlike mere thickness worths, nonetheless, even more elements enter into the recreation of great information other than thermal expansion.

Best Cad Software For 3d Printing

FDM 3D printing produces items by squeezing out thermoplastics through a heated nozzle. Objects are published one layer at once, and these layers cool at different rates depending upon their size and framework. This can trigger warping and slight variations in the precision of the final things. Materials that need higher print temperature levels, like ABS, have a greater threat of bending. 3D printing is an imperfect procedure. Decisions that affect the last dimensional accuracy can be made while designing the things, choosing a printing technique and picking the materials that the object will certainly be made from.

Maruyama, T., Hirata, H., Furukawa, T. & Maruo, S. Multi-material microstereolithography utilizing a scheme with multicolor photocurable materials. Express 10, 2522. Fang, T.-S., Brown, R. E., Kwan, C. L. & Singer, L. A. Photophysical researches on benzil.

A review of the background reveals that a variety of products (resins, plastic powder, plastic filament and hot-melt plastic ink) were utilized in the 1980s for licenses in the quick prototyping area. The term "3D printing" initially referred to a process that transfers a binder product onto a powder bed with inkjet printer heads layer by layer. Much more lately, the prominent vernacular has begun using the term to incorporate a wider variety of additive-manufacturing methods such as electron-beam additive manufacturing and careful laser melting. The USA and global technical requirements make use of the main term additive production for this broader sense. 3D printing is an additive manufacturing process that creates things by building layers upon layers of product till the last things is developed.

The business's tools for Custom-Designed Murals recording and assessing information are bringing this vision more detailed to reality. Find out how to prevent poor quality 3D prints or needlessly big files by exporting your STL file in the proper resolution. This article explores the fundamentals of how and when to utilize GD&T to get the very best outcomes out of custom component production.

The business's tools for Custom-Designed Murals recording and assessing information are bringing this vision more detailed to reality. Find out how to prevent poor quality 3D prints or needlessly big files by exporting your STL file in the proper resolution. This article explores the fundamentals of how and when to utilize GD&T to get the very best outcomes out of custom component production.

Filaments And Artistic Wall Murals Materials Utilized In 3d Printing

Additionally described as SL, optical fabrication, please click the next site photo-solidification, or resin printing. New Bioprinter Makes It Easier to Make 3D Flesh and Bone by Eliza Strickland. Besides substitute body components, 3D printing is increasingly being used for medical education and learning and training. At Nicklaus Children's Healthcare facility in Miami, Florida, specialists practise surgical treatment on3D-printed reproductions of kids's hearts. Rarely the realm of enthusiasts, 3D printing is poised to overthrow manufacturing and reinvent aerospace. They can be available in steel, brass, bronze and copper so as to get the true feel and look of a metal object.

Additive manufacturing, starting with today's infancy period, requires manufacturing companies to be flexible, ever-improving users of all offered modern technologies to remain affordable. The real assimilation of the newer additive technologies into industrial production, however, is a lot more an issue of matching standard subtractive techniques rather than displacing them totally. Fluid additive production is a 3D printing method that deposits a fluid or high viscose product (e.g. liquid silicone rubber) onto a develop surface area to develop an object which after that is vulcanised making use of heat to solidify the things. The process was originally developed by Adrian Bowyer and was after that built upon by German RepRap.

Innovation

The product utilized in 3D printing is typically in the kind of a filament or a resin. Filaments, such as thermoplastics or metals, are fed right into the printer and melted at a certain temperature before being extruded click through the next article a nozzle. Resins, on the various other hand, are treated using ultraviolet light or various other methods. As soon as the design documents prepares, it is transferred to the 3D printer, which after that equates the electronic model right into a physical item. The printer accomplishes this by transferring material layer by layer, adhering to the guidelines encoded in the layout documents.

Just how much resistance you agree to approve is pretty much your phone call, however there are methods for you to decrease the tolerance you can get out of your 3D printer. These actions can be summarized as absolutely nothing greater than picking the appropriate product and doing routine maintenance on your maker. Appropriate calibration plays a big part-- we suggest finding out the best practices on calibrating your 3D printer's various components. Fine information in a model are a bit harder to define, as they are typically a mix of several printing specifications. Unlike mere thickness worths, nonetheless, even more elements enter into the recreation of great information other than thermal expansion.

Best Cad Software For 3d Printing

FDM 3D printing produces items by squeezing out thermoplastics through a heated nozzle. Objects are published one layer at once, and these layers cool at different rates depending upon their size and framework. This can trigger warping and slight variations in the precision of the final things. Materials that need higher print temperature levels, like ABS, have a greater threat of bending. 3D printing is an imperfect procedure. Decisions that affect the last dimensional accuracy can be made while designing the things, choosing a printing technique and picking the materials that the object will certainly be made from.

Maruyama, T., Hirata, H., Furukawa, T. & Maruo, S. Multi-material microstereolithography utilizing a scheme with multicolor photocurable materials. Express 10, 2522. Fang, T.-S., Brown, R. E., Kwan, C. L. & Singer, L. A. Photophysical researches on benzil.

A review of the background reveals that a variety of products (resins, plastic powder, plastic filament and hot-melt plastic ink) were utilized in the 1980s for licenses in the quick prototyping area. The term "3D printing" initially referred to a process that transfers a binder product onto a powder bed with inkjet printer heads layer by layer. Much more lately, the prominent vernacular has begun using the term to incorporate a wider variety of additive-manufacturing methods such as electron-beam additive manufacturing and careful laser melting. The USA and global technical requirements make use of the main term additive production for this broader sense. 3D printing is an additive manufacturing process that creates things by building layers upon layers of product till the last things is developed.

The business's tools for Custom-Designed Murals recording and assessing information are bringing this vision more detailed to reality. Find out how to prevent poor quality 3D prints or needlessly big files by exporting your STL file in the proper resolution. This article explores the fundamentals of how and when to utilize GD&T to get the very best outcomes out of custom component production.

The business's tools for Custom-Designed Murals recording and assessing information are bringing this vision more detailed to reality. Find out how to prevent poor quality 3D prints or needlessly big files by exporting your STL file in the proper resolution. This article explores the fundamentals of how and when to utilize GD&T to get the very best outcomes out of custom component production.댓글목록

등록된 댓글이 없습니다.

.png)

.png)